Overview

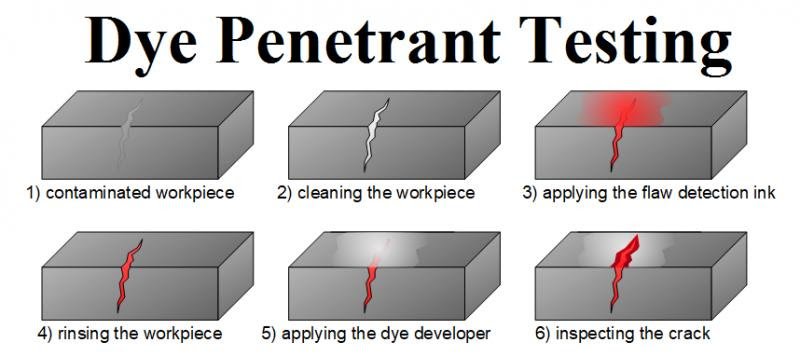

Also known as Liquid penetrant inspection, Dye Penetrant testing is the most reliable

method of finding defects and discontinuities opened on the surface especially in all

non-porous materials. This method is widely used for testing of non-magnetic materials.

Service Details

In PT method, a liquid/dye penetrant is applied to the surface of the product for a certain

predetermined time specified by codes, standards or specifications, after which the

excess penetrant is removed from the surface. The surface is then dried and a

developer is applied to it. The penetrant which remains in the discontinuity is absorbed

by the developer to indicate the presence as well as the location, size and nature of the

discontinuity. Penetrants used are either visible dye penetrant or fluorescent dye

penetrant. The inspection for the presence of visible dye indications is made under

white light while inspection of presence of indications by fluorescent dye penetrant is

made under high intensity ultraviolet (or black) light under darkened conditions.

The Liquid penetrant testing facility is provided:

With ultra sensitive, high sensitive, medium sensitive penetrant materials suitable for structural to aerospace applications. Experienced in-house ASNT NDT Level IIIs for

preparing, approving NDT procedures